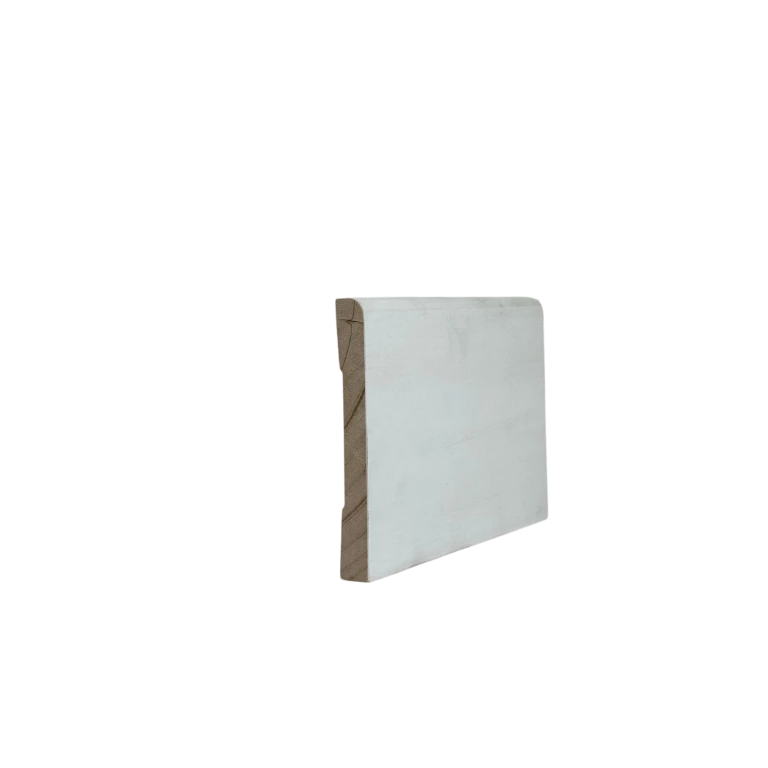

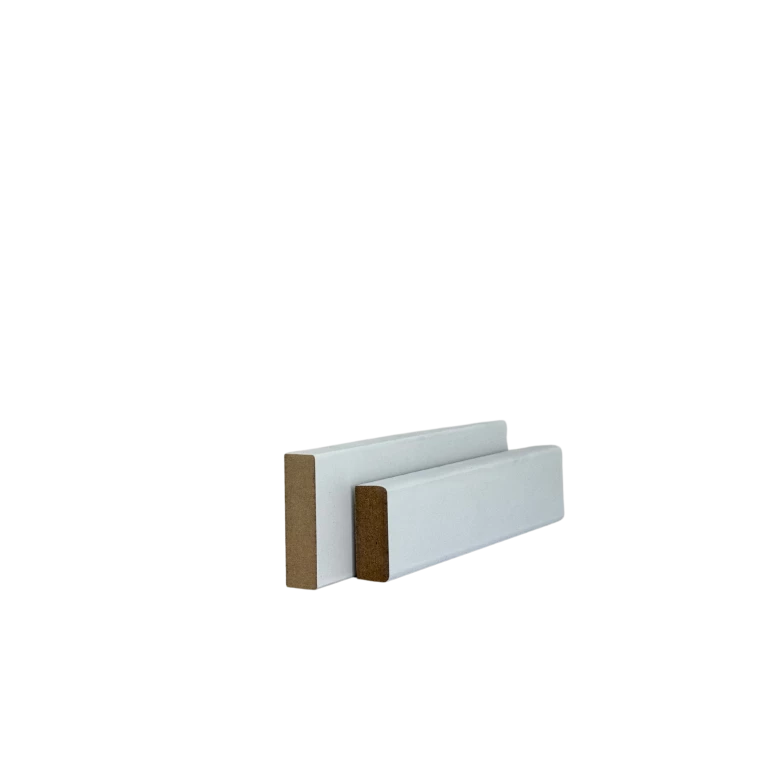

Made with high-quality materials to ensure long-lasting performance and reliability. Our expert team is here to help you select the perfect jambs, frames, and cavity sliders for your project.

Jambs & Frames + STD Cavity sliders Highlights

Variety of sizes

Our jambs, frames, and cavity sliders come in a range of standard sizes to suit various project requirements.

Quick availability

All products are kept in stock or can be ordered, ensuring fast turnaround for your project.

Easy Installation

Designed for quick and hassle-free installation, saving time and effort on-site.

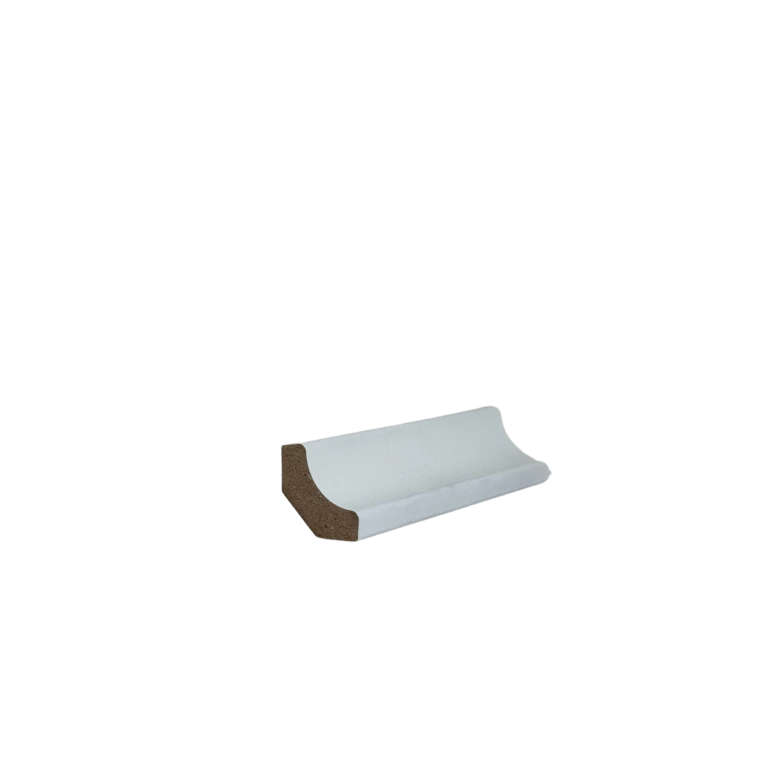

Our Jambs & Frames + STD Cavity sliders

Barn Doors

Barn doors are no longer just for barns. Wide sliding doors have entered modern houses to become popular interior decor pieces with exposed hardware and Rustic finishes creating cosy hide away bedrooms to rustic home office doors and unique wardrobe solutions.

Custom Timber Skirting options

Installation

No, Eva-Last decking does not need sealing or staining. The protective capping ensures long-lasting colour and durability without ongoing treatment.

Yes, the recommended screws depend on the decking range:

- Avenue range: use Cobra T-clips for hidden fastening. These clips allow for proper board spacing and thermal expansion. For edge boards, use self-drilling screws.

- Terrace range: install grooved boards with Cobra T-clips, and for square-edge boards, use stainless steel screws for secure direct fixing.

- Coastal range: similar to other ranges, use Cobra T-clips for hidden fixing and Stainless Steel screws for perimeter boards or direct fastening.

NO, MODWOOD DECKING DOES NOT REQUIRE SEALING OR STAINING. HOWEVER, A SEALER CAN BE APPLIED TO AREAS THAT MAY BE PRONE TO HIGH LEVELS OF STAINING, SUCH AS UNDER COVERED SPACES OR ALFRESCO AREAS

Yes, Eva-Last composite boards can be used for fascia applications, enhancing the look of your deck while providing durability and low maintenance. Ensure you select compatible boards for fascia use.

Yes, NewTechWood offers solid boards specifically designed for fascia and vertical applications. These boards provide a clean, seamless finish for staircases, edges, and other non-decking areas.

Eva-Last recommends Hulk fasteners, made from durable materials like 304-grade stainless steel, for secure installation and corrosion resistance. These fasteners are designed to prevent damage to the boards, provide a seamless finish, and are available in colours matching the decking for a polished look.

NO, MILLBOARD DECKING DOES NOT REQUIRE SEALING, STAINING, OR PAINTING. ITS DURABLE OUTER LAYER IS DESIGNED TO RESIST FADING, STAINING, AND WEAR, MAINTAINING ITS APPEARANCE WITH MINIMAL UPKEEP.

No, the Ultrashield® coating eliminates the need for sealing or staining, ensuring a low-maintenance surface resistant to fading, staining, and scratches.

NewTechWood recommends using stainless steel screws to prevent rust and maintain durability. Alternatively, their cobra hidden fastener system is specifically designed for a seamless finish and proper spacing.

MILLBOARD RECOMMENDS USING DURAFIX? SCREWS SPECIFICALLY DESIGNED FOR ITS DECKING. THESE SCREWS SELF-COUNTERSINK AND ELIMINATE THE NEED FOR PRE-DRILLING.

For natural timber decking, use high-quality screws to ensure durability and a secure finish. Recommended options include:

- Blackhawk countersunk BH103D power 10: versatile and reliable for general applications.

- Blackhawk speed drive SS304 BH106D (10g x 50mm): ideal for environments with moderate exposure to moisture.

- Blackhawk speed drive SS316 BH108D and BH109D (10g x 50/65mm): perfect for high-corrosion areas, such as coastal locations.

- Wurth A2 deck screw 16675550: highly resistant to rust and suitable for all outdoor decking applications.

- Wurth RW20 driver bit (luminous orange): ensures smooth installation with precise fit.

Using stainless steel screws helps maintain the structural integrity and aesthetic of your timber decking.

We stock a variety of Blackhawk and Wurth stainless steel screws, as well as tools like Wurth RW20 driver bits for professional-grade installations, and brushes for oils and tint applications.

Yes, Eva-Last strongly recommends using their Hulk fasteners, which are specifically engineered for composite decking. These fasteners are designed to provide maximum hold without damaging the boards, thanks to their self-drilling capabilities and advanced thread design. Hulk fasteners are made from durable materials like 304-grade stainless steel, offering excellent resistance to corrosion, especially in coastal or humid environments.

Additionally, they are available in a range of colours to match the decking, ensuring a seamless and polished finish. Using these recommended fasteners not only ensures a professional installation but also maintains your deck’s warranty.

Trex recommends using the following fasteners for secure and aesthetically pleasing installation:

- Trex hideaway? hidden fasteners: these provide a smooth, screw-free deck surface.

- Trex ? decking screws: these are designed for visible fastenings with stainless steel or coated options to prevent corrosion.

We do not provide installation services directly; however, we work with trusted installers who can assist with your decking project. for recommendations, please contact our decking specialists at 08 9434 5775 or sales@franzbuildingsupplies.com.au and we'll be happy to connect you with an experienced installer in your area.

MODWOOD RECOMMENDS USING APPROPRIATE SCREWS SPECIFIED IN THEIR INSTALLATION GUIDE TO ENSURE A SECURE FIT AND AVOID SPLITTING OR DAMAGE. FOR CONCEALED FIXING, THE MODWOOD KLEVAKLIP SYSTEM IS HIGHLY RECOMMENDED

General

We supply both trade professionals and the general public. whether you're a contractor, builder, or diy enthusiast, you’re welcome to shop with us.

Customers are welcome to collect their orders from our premises, conveniently located at Franz Building Supplies, c2/174 Barrington Street, Bibra Lake wA 6163. Our collection hours are monday to thursday from 7:00 am to 4:30 pm and friday from 7:00 am to 4:00 pm. we are closed on saturdays and sundays.

to streamline your collection experience, we encourage you to contact us in advance at (08) 9434 5775 or email sales@franzbuildingsupplies.com.au. confirming your order and ensuring your vehicle is suitable for transporting your items helps ensure a smooth process.

transportation safety

at franz building supplies, safety is a priority. goods will only be released if the customer has a vehicle capable of securing the load safely and legally. western australian law strictly prohibits the transport of unsecured loads to ensure public road safety, and we adhere to these regulations by refusing the release of goods intended for unsafe transport.

to assist customers, here are key guidelines:

- for cars (sedans or suvs), loads must not extend more than 1.2 meters beyond the front or rear of the vehicle and cannot exceed 150 millimeters past the sides. roof load limits are typically around 50 kg, including the weight of roof racks.

- for utes, rear loads must not extend more than 1.2 meters beyond the tray without a visible flag or marker. roof racks on utes can generally support up to 100 kg, provided the load is evenly distributed.

it is essential that all loads are securely fastened to prevent shifting during transit. both overloading and uneven distribution can compromise safety and are strictly prohibited under western australian regulations.

need assistance?

if you have any questions or need assistance with collections or deliveries, our team is here to help. please contact us at (08) 9434 5775 or email sales@franzbuildingsupplies.com.au, and we will be happy to assist.

Yes, our on-site workshop can custom-run mouldings, weatherboards, and standard doors to suit specific design needs. we also offer bespoke joinery through our sister company, abbott'solutely timber joinery.

We provide trade accounts and tailored pricing for industry professionals. contact us to learn more about eligibility and account setup.

Our experienced team is here to assist with more than just decking, cladding, and joinery. we provide expert advice across a wide range of building materials, including timber, hardware, fixings, and architectural elements. whether you’re working on a residential renovation, commercial build, or custom joinery, we’ll guide you in choosing the best products for your specific requirements. from design concept to material selection, we aim to ensure your project runs smoothly and meets your expectations.

If you have any questions or need further assistance with your collection or delivery, please contact us at (08) 9434 5775 or email sales@franzbuildingsupplies.com.au. our team is happy to assist and ensure a seamless experience.

You can collect your order from our premises at franz building supplies, located at c2/174 barrington street, bibra lake wa 6163. our collection hours are monday to thursday from 7:00 am to 4:30 pm and friday from 7:00 am to 4:00 pm. we are closed on saturdays and sundays.

To maintain smooth operations, we request that any changes or cancellations to your delivery be communicated to us at least 24 hours before the scheduled time. this ensures that we can adjust our schedules and provide the best service possible.

Yes, we provide cutting services to help you get materials prepared to your exact specifications. contact us for details on this service.

To arrange a collection, please contact us at (08) 9434 5775 or email sales@franzbuildingsupplies.com.au. we recommend confirming your order and ensuring your vehicle is suitable for transporting your items before arriving to ensure a smooth process.

If you have any questions or need further assistance with your collection or delivery, please contact us at (08) 9434 5775 or email sales@franzbuildingsupplies.com.au. our team is happy to assist and ensure a seamless experience.

Franz building supplies will accept goods back into stock under specific conditions. goods must be in a re-sellable condition, as determined by the company, and must have been delivered or collected within the last 30 days.

returns due to over-ordering, a change of mind, or an error made by the customer will incur a restocking fee. however, if an error was made by franz building supplies in the supply of goods, no restocking fee will apply. credits for returned goods will only be processed once the items have been inspected and confirmed to be in a re-sellable condition.

for items held in stock by franz building supplies, a restocking fee of 15% of the customer’s invoice value will apply, up to a maximum of $250 plus gst. if collection of the goods from the customer’s site is required, additional pickup fees will apply: $80 plus gst for a hand load pickup or $150 plus gst for a hiab pickup.

for items not held in stock, returns will only be accepted if the goods can be returned to the supplier. customers must arrange this return with the supplier prior to returning the goods to franz building supplies' warehouse. a minimum restocking fee of 15% of the customer’s invoice value will apply, and if the supplier charges a higher restocking fee, that charge will be passed on to the customer. there is no maximum restocking fee for non-stock items, as supplier charges may vary. pickup fees for non-stock items will also apply: $80 plus gst for a hand load pickup or $150 plus gst for a hiab pickup.

for any returns or requests that fall outside these guidelines, customers are advised to contact the sales team at franz building supplies by calling 08 9434 5775 or emailing sales@franzbuildingsupplies.com.au and a team member will respond to assist.

Our delivery fees are as follows:

$150.00 + gst for orders that require a hiab unload (typically larger orders).

$80.00 + gst for orders that can be hand unloaded (such as skirting, mouldings, doors, hardware, or small timber orders).

Absolutely. we specialise in matching existing profiles for renovation and restoration projects to ensure consistency in design and finish.

For a successful delivery, please ensure our driver has access to the delivery location. our driver will call upon arrival. if access is not available and goods cannot be delivered, the delivery fee will still apply. the goods will be returned to our premises, and you can either pay for a redelivery or arrange your own collection.

We do not provide installation services directly; however, we work with trusted installers who can assist with your decking project. for recommendations, please contact our decking specialists at 08 9434 5775 or sales@franzbuildingsupplies.com.au and we'll be happy to connect you with an experienced installer in your area.

At franz building supplies, we are committed to providing quality products and ensuring the safe delivery of all orders. to ensure a smooth and transparent process, we have outlined the following guidelines regarding the handling of damaged goods:

proof of delivery

once a delivery is complete, our driver will take a photograph of the goods as proof of delivery. this photo will serve as documentation that the goods were delivered in good condition at the time of delivery.

reporting damaged goods

if you discover that any goods are damaged upon delivery, you must notify us immediately. claims regarding damaged goods must be reported within 24 hours of delivery to ensure a prompt resolution. additionally, we require that you provide evidence that the damage occurred during transit and that franz building supplies is at fault. please note that this does not guarantee a refund or replacement.

responsibility for damage after delivery

if goods are damaged or stolen after the delivery is completed, franz building supplies is not responsible for any losses. our liability for goods ceases once the delivery is made, and the driver has captured proof of delivery.

replacement of damaged goods

if goods are found to be damaged due to factors beyond our control (e.g., handling by the customer, theft, or third-party damage), we are unable to provide a refund or replacement at no charge. if replacement goods are required, these will be charged to the customer at the full price.

we recommend inspecting all items at the time of delivery and immediately notifying our team of any discrepancies or damages so that we can address the situation as quickly as possible.

for any further questions or to report damaged goods, please contact us at (08) 9434 5775 or email sales@franzbuildingsupplies.com.au.

Yes — our team can help you select hardware that suits your project’s style, function and technical requirements. Whether you’re replacing existing fittings or starting from scratch, we’re here to assist.

Deliveries are available for the perth metro area, covering regions from secret harbour to butler. for deliveries outside of this area, delivery fees are available upon request. to arrange a delivery, please contact us at (08) 9434 5775 or email sales@franzbuildingsupplies.com.au, and we will coordinate a suitable delivery time.

Architectural hardware includes the functional and decorative fittings used on doors, windows and joinery. This covers items like handles, locks, hinges, sliding systems and seals that enhance both the performance and appearance of a space.

Performance and Durability

MILLBOARD DECKING UNDERGOES MINIMAL EXPANSION AND CONTRACTION DUE TO ITS POLYMER CORE. THIS MAKES IT STABLE IN EXTREME TEMPERATURES AND PREVENTS GAPS OR WARPING.

Use Cutek Extreme CD50 or Cutek wood preservative, which penetrate deeply to reduce moisture fluctuations. Regular maintenance keeps the timber stable and reduces the risk of splitting over time.

YES, MODWOOD FLAME SHIELD® DECKING IS RATED FOR BUSHFIRE-PRONE AREAS WITH A BAL-40 RATING, MAKING IT SUITABLE FOR HIGH-RISK ZONES. HOWEVER, STANDARD MODWOOD BOARDS ARE NOT FIRE-RATED AND CANNOT BE USED IN SUCH AREAS

Eva-Last composite decking is ideal for water-adjacent installations. Its moisture-resistant properties and anti-slip surface make it suitable for docks, pool surrounds, and beachfront properties.

Yes, species like jarrah and Spotted Gumare naturally resistant to moisture. Enhance their protection with Cutek Extreme CD50, which resists fungal decay and controls moisture absorption.

Trex composite decking is built to last for decades, typically offering a 25-year lifespan or longer with proper care. The material is resistant to many of the issues that affect traditional wood, such as warping, rotting, and splintering.

Composite decking naturally expands and contracts with temperature changes. Proper installation with recommended gapping allows the boards to adjust without affecting their appearance or performance.

NO, MILLBOARD DECKING IS HIGHLY RESISTANT TO FADING. ITS UV-STABLE SURFACE MAINTAINS ITS VIBRANT COLOUR FOR YEARS, EVEN IN DIRECT SUNLIGHT.

Yes, Trex composite decking expands and contracts with temperature fluctuations, as with most composite materials. To account for this natural movement, it?s essential to leave a gap between boards during installation. The recommended gap is 5mm to 8mm for end-to-end board spacing and 3mm to 5mm between side edges of the boards. These gaps ensure that the decking can expand and contract without causing buckling or warping.

Trex composite decking is designed to resist fading due to its durable, capped surface, but slight fading may occur over time due to exposure to the sun. However, it maintains its colour longer than many other decking options.

While Trex composite decking is scratch-resistant, it is not scratch-proof. Heavy furniture or sharp objects can cause scratches. Trex 's surface is designed to withstand normal wear, but it's advisable to avoid dragging furniture or sharp items across it.

NewTechWood decking features a fully capped layer that provides excellent UV protection. This means the boards retain their colour for many years, even in harsh sunlight, with only minor natural weathering.

Composite decking naturally expands and contracts with like all composite materials, Eva-Last decking experiences minor expansion and contraction with temperature changes. Proper installation with recommended spacing allows for this natural movement without affecting the deck’s performance.

NO, MILLBOARD?S DURABLE SURFACE IS RESISTANT TO SCRATCHES FROM NORMAL USE, INCLUDING FOOT TRAFFIC AND FURNITURE.

Eva-Last’s capped composite decking, like the Infinity and ApexPlus ranges, features scratch-resistant surfaces. However, using furniture pads and avoiding dragging heavy objects can help maintain the deck's pristine look.

Trex composite decking is ideal for wet environments like poolside or by the beach due to its moisture-resistant properties. The decking will not absorb water, which helps prevent mould and mildew growth.

Yes, it is highly water-resistant and ideal for use in coastal areas or poolside. The capped surface prevents moisture absorption, protecting against swelling, rotting, or warping.

Hardwoods like Spotted Gumand Blackbutt meet Australian bushfire resistance standards, making them suitable for decking in bal-rated areas.

Yes, like most outdoor materials, composite decking can absorb heat in direct sunlight, especially darker colours. To keep your deck cooler, consider lighter-coloured boards or adding shaded areas such as a pergola or awning.

Hardwoods like merbau, jarrah, and Spotted Gumoffer excellent durability. Apply Cutek Extreme CD50 to maximise longevity and enhance their natural resistance to weathering and decay.

Trex composite decking has a Class B fire rating, which means it is resistant to fire spread, making it a safer option for many residential applications. However, it is not entirely fireproof.

YES, MILLBOARD DECKING IS WATER-RESISTANT AND SUITABLE FOR USE NEAR POOLS, DOCKS, AND OTHER WATER FEATURES. ITS NON-POROUS SURFACE PREVENTS WATER ABSORPTION AND ROT.

Yes, Trex composite decking is made from 95% recycled materials, including reclaimed wood and plastic. This makes Trex a sustainable option for decking, reducing the environmental impact compared to traditional wood.

The ultra-durable capped layer resists everyday wear, including scratches, stains, and scuffs. While no surface is entirely scratch proof, the boards are designed to withstand regular use without noticeable damage.

MODWOOD BOARDS EXPERIENCE MINIMAL COLOR FADE AFTER THEIR INITIAL WEATHERING PERIOD OF A FEW MONTHS. THIS PROCESS ALLOWS THEM TO SETTLE INTO THEIR NATURAL, LONG-LASTING TONES

YES, LIKE ALL COMPOSITE MATERIALS, MODWOOD EXPANDS AND CONTRACTS WITH TEMPERATURE CHANGES. ADEQUATE SPACING DURING INSTALLATION IS NECESSARY TO ACCOUNT FOR THIS MOVEMENT

Eva-Last products are engineered to resist fading. With UV-resistant capping technology, ranges like Infinity and ApexPlus maintain their vibrant colour for years, even under harsh sunlight.

Trex recommends using screws designed for composite decking, such as those made from stainless steel or coated to resist corrosion. Avoid using regular wood screws as they can cause splitting or rust.

Hardwoods like jarrah, spotted gum, and merbau offer exceptional durability, natural resistance to termites and decay, and stunning aesthetics with rich grain patterns.

Yes, NewTechWood decking meets Australian fire safety standards and is rated for use in areas requiring BAL-29 compliance, making it suitable for bushfire-prone regions.

Yes, timber naturally weathers to a silver-grey patina. To preserve or enhance its original tone, apply Cutek Colourtones, available in shades like rustic gold and black ash. Regular applications of Cutek Extreme CD50 help slow down the weathering process.

Trex composite decking consists of a blend of recycled wood fibres and plastic, providing a durable, eco-friendly material. The decking is capped with a protective layer that helps prevent stains and fading while also making it low maintenance.

With proper maintenance, hardwood decking like Spotted Gumand jarrah can last 30 years or more, while treated pine provides excellent performance at a lower cost.

MODWOOD IS DESIGNED TO RESIST SCRATCHES, PARTICULARLY ON ITS BRUSHED SURFACE. HOWEVER, HEAVY OR SHARP OBJECTS MAY STILL CAUSE MARKS. PROTECTIVE PADS ON FURNITURE LEGS CAN HELP MINIMIZE SCRATCHES

MODWOOD IS IDEAL FOR USE IN MARINE OR POOLSIDE ENVIRONMENTS. IT IS RESISTANT TO SALT AIR AND WILL NOT SPLINTER, MAKING IT SAFE FOR BARE FEET

Yes, certain Eva-Last decking products meet fire resistance standards. Apex, for example, achieves BAL-29 fire ratings, making it suitable for bushfire-prone areas in Australia.

MODWOOD DECKING IS BUILT FOR LONGEVITY AND CAN LAST FOR DECADES WITH MINIMAL MAINTENANCE. ITS DURABILITY DEPENDS ON PROPER INSTALLATION AND CARE

MILLBOARD DECKING IS DESIGNED TO LAST OVER 25 YEARS WITH MINIMAL MAINTENANCE, MAINTAINING ITS STRUCTURAL INTEGRITY AND AESTHETIC APPEAL.

MILLBOARD COMPOSITE DECKING HAS A BAL-19 RATING UNDER THE AUSTRALIAN BUSHFIRE STANDARDS, MEANING IT CAN BE USED IN AREAS THAT REQUIRE THIS LEVEL OF FIRE RESISTANCE, PROVIDED IT IS INSTALLED WITHIN A COMPLIANT SYSTEM. THE RATING INDICATES THAT IT IS SUITABLE FOR ENVIRONMENTS PRONE TO EMBER ATTACKS, RADIANT HEAT UP TO 19 KW/M?, AND SOME WIND-BORNE DEBRIS WITHOUT IGNITING. THIS MAKES MILLBOARD A PRACTICAL OPTION FOR ENHANCING FIRE SAFETY IN DECKING APPLICATIONS

Yes, Trex composite decking expands and contracts with temperature fluctuations, as with most composite materials. To account for this natural movement, it?s essential to leave a gap between boards during installation. The recommended gap is 5mm to 8mm for end-to-end board spacing and 3mm to 5mm between side edges of the boards. These gaps ensure that the decking can expand and contract without causing buckling or warping.

Get a product custom built by our expert craftsmen.

Get your project underway today

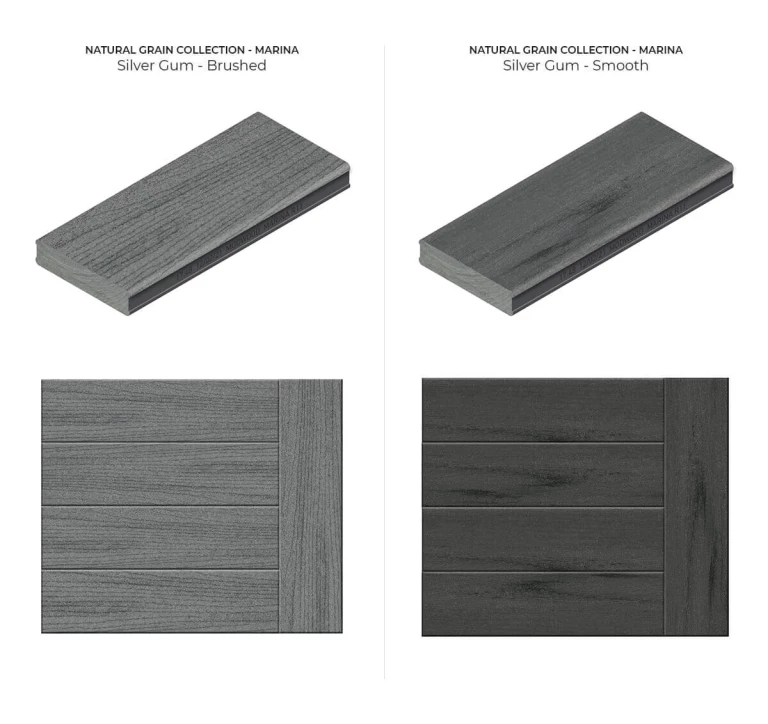

Featured Products

Stocking the brands you know and trust

At Franz Building Supplies, we pride ourselves on stocking the brands you know and trust, ensuring quality and reliability for every project. From trusted names in timber to innovative solutions for decking, cladding, and more, our range is designed to help you create with confidence.